Table of Contents

Finally 10 Second Passes – But At What Cost

We know our core business isn’t building quick street cars for the strip, but it sure is fun learning and reaching the goals we set ourselves. After hours of work getting the blower drive and engine combo dialled in on our ECUWest workshop VE SS, it was finally time to test it out down the Motorplex again. With a conservative E85 tune & keeping the 4.0L Whipple Blower from getting over 20PSI of boost, we finally got the better of the head gasket issues which were plaguing us earlier in the year. After going over it all again for the 100th time we packed her up on the trailer and headed for the Perth Motorplex to see if we could make it the other end without flicking a blower belt or some other teething issue stopping us. Being a 6 speed manual its a bit of a handful but with a lot of nerves and excitement, the ECUWest crew could finally see the fruits of our labour. The car performed well and we managed to get a few reasonable runs. Engine, blower, interchiller temps all going well. The only weak link starting to emerge was the was the NPC clutch, but in fairness it was built for our previous combo. We were more than happy with the high ten second passes we were achieving. The more runs we did the more confident we grew in how the car was going although the clutch was preventing us from bettering a 10.8 ET.

Until a bit of clutch shudder or wheel spin caused some diff hop off the launch, when we hit second there was a massive bang with sparks…. great entertainment for the crowd. Some lucky kid in the stands got a hot Nolathane diff bushing that was only a few hours old…

Assessing & Removing The Carnage

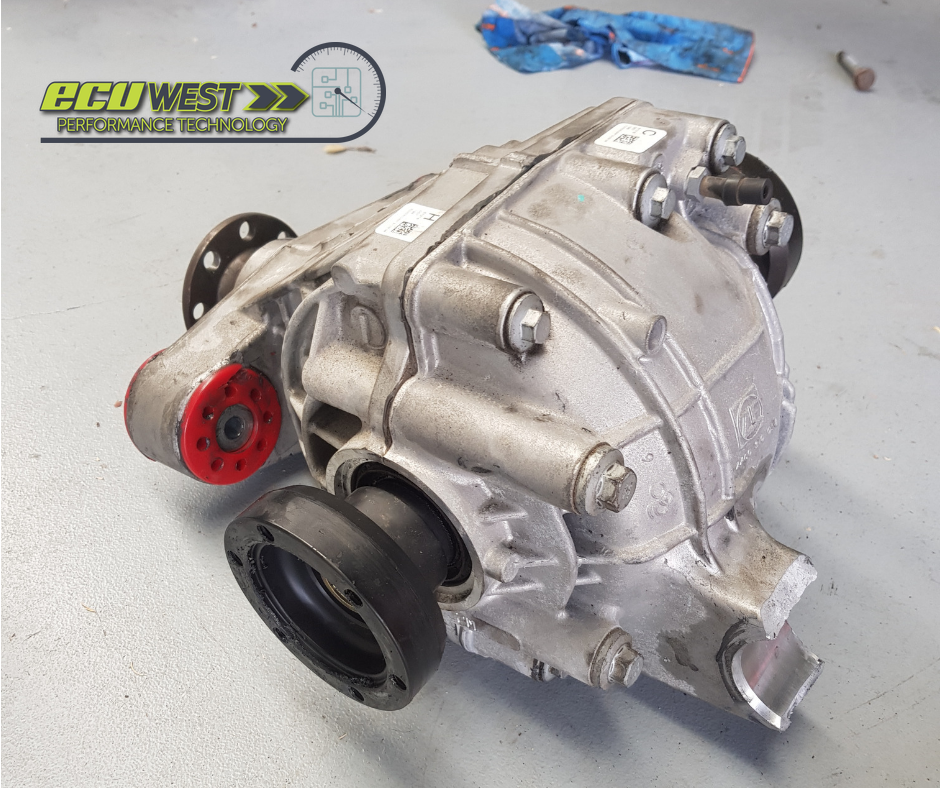

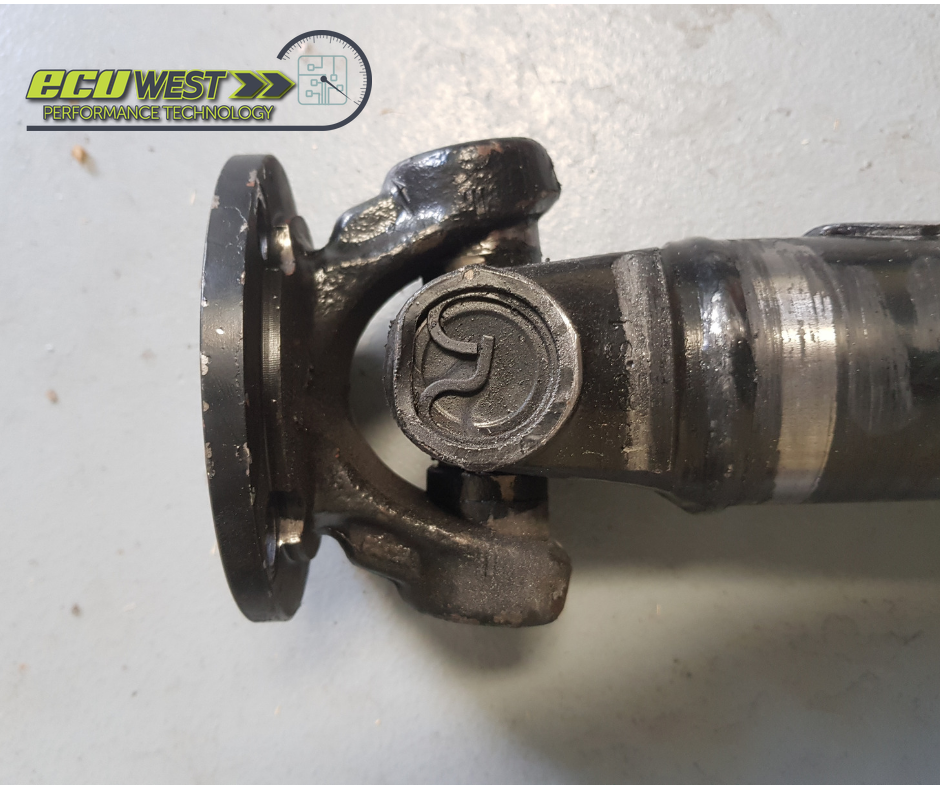

The ute made it to half track and loudly limped back to the pits where we loaded her onto the trailer. A quick look revealed the rear differential housing mount could not take the torque and had snapped clean off. The built internals and axles held up their end but the housing itself was the weak point that failed. The next day we put the car on the hoist and had a better look. Not only were we looking at a broken differential housing but it destroyed the rear sub frame and diff cradle, moving the upper control arms over 15mm in their mounts. The massive uni in the built drive shaft had splayed open like it was made of plastic, the exhaust system was damaged and the fuel cell had taken a hit too. It was a shock to see how much damage had actually been done.

Starting From Scratch – Again

The build route, components & setup we were advised to take wasn’t at all suitable or up to the task. So we contacted Billy from G-Force Engineering in Wichita Kansas. He said it was a common weak point & failure in the Camaro & Corvette’s – anything over 850 RWHP will break the diff housing and kill the rest of the rear end. This is mainly due to diff hop or axle tramp.

So we took his advice and went for their 9″ IRS Kit with 1500hp anti hop Outlaw Axles. Having one axle engineered to be a greater torsional strength than the other eliminates the diff hop.

We will need to get our drive shaft repaired and modified to suit the new 9″ diff yoke.

Part 2 Getting All Of Our New Parts Together

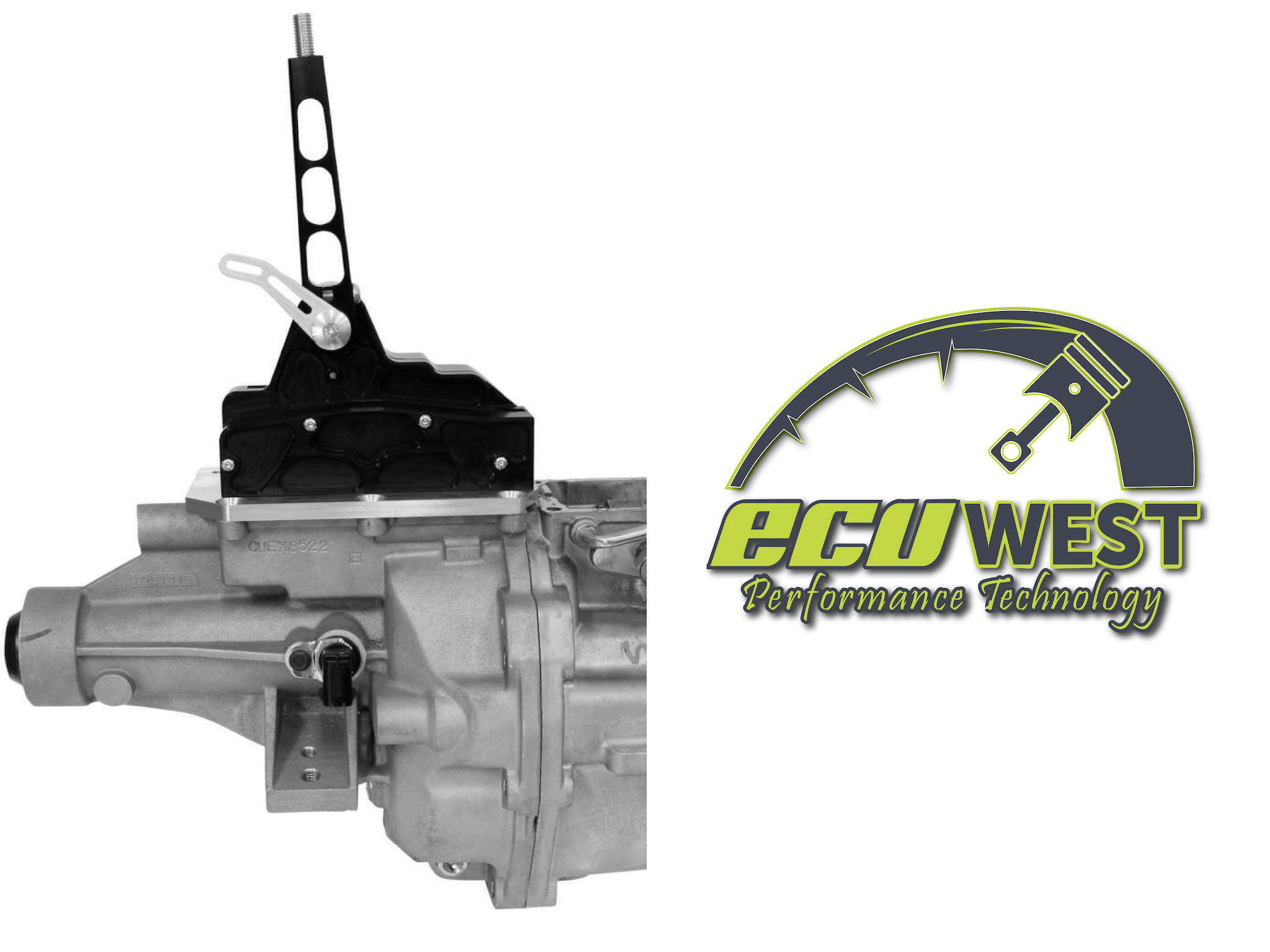

In Part 2 we’ll start putting all the new and upgraded parts together, plus a couple of nice touches like the S1 Sequential Shifter for our Magnum XL Transmission. Waiting for the Christmas break to finish will be frustrating….